Product Description

Straight panel Tapet panel bemo panel rollformer

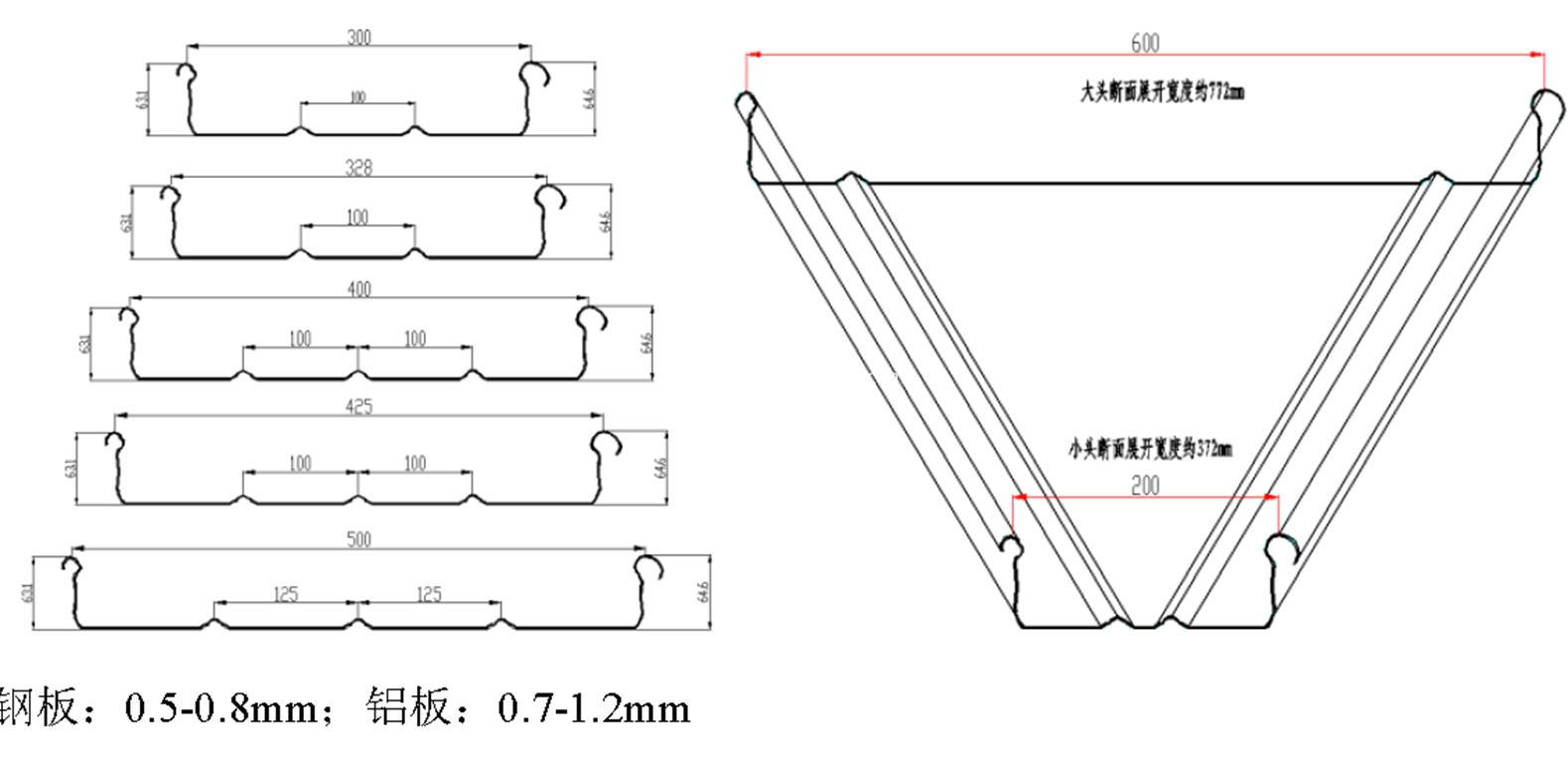

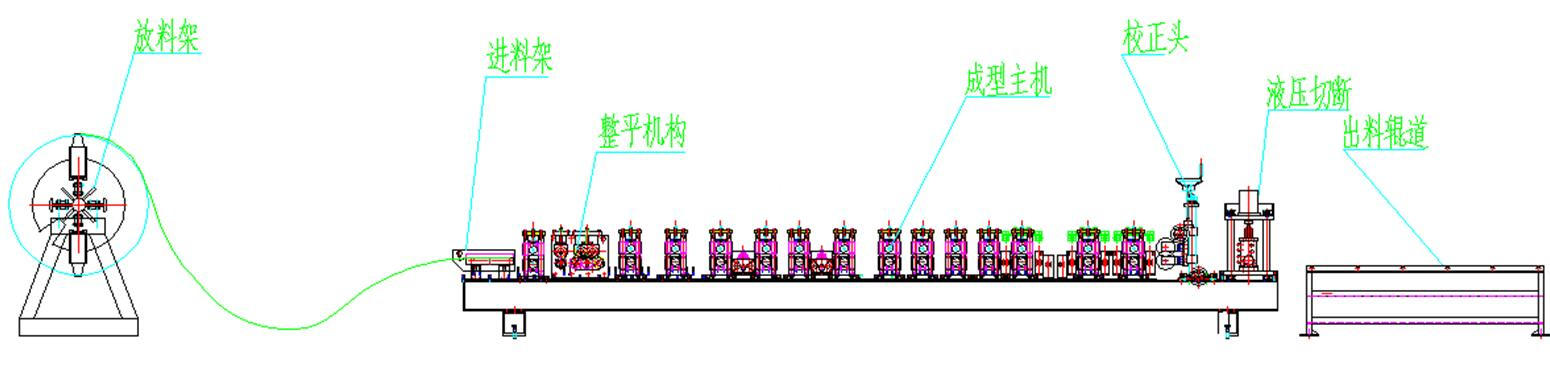

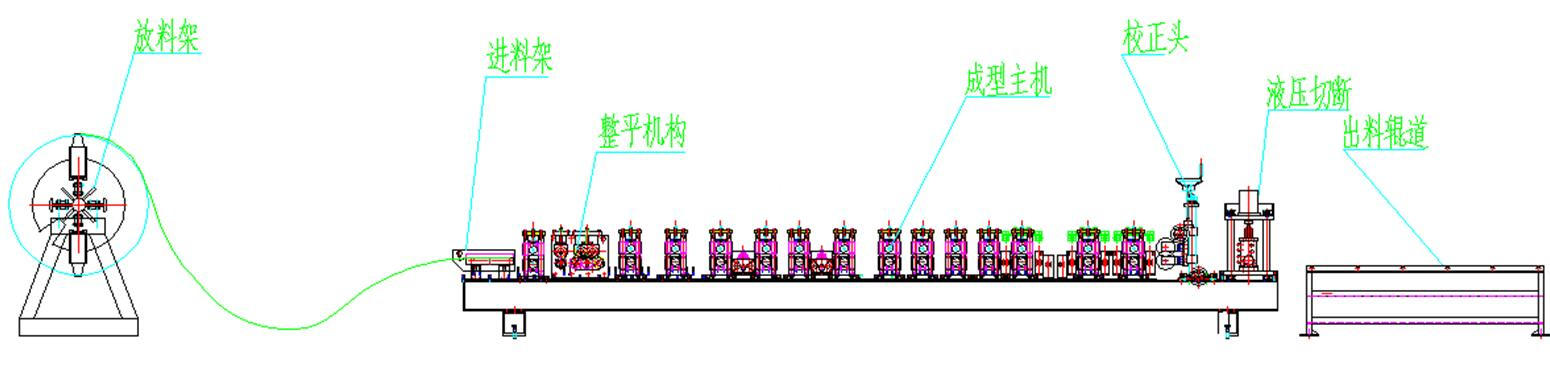

Straight panel Tapet panel bemo panel rollformer can produce the bemo panel both straight and tapet panel. The straight panel width is 300mm,328mm,400mm,425mm,500mm. steel Bemo thickness is 0.5-0.8mm,aluminium panel thickness 0.7-1.2mm. The tapet panel wider end width is 600mm, narrow end width is 200mm.

For the tapet panel , with the different size end, this special forming processing roots from the designing and installation of the forming rollers. the forming rolllers are with a shape from big to small.

below are some pictures for your reference:

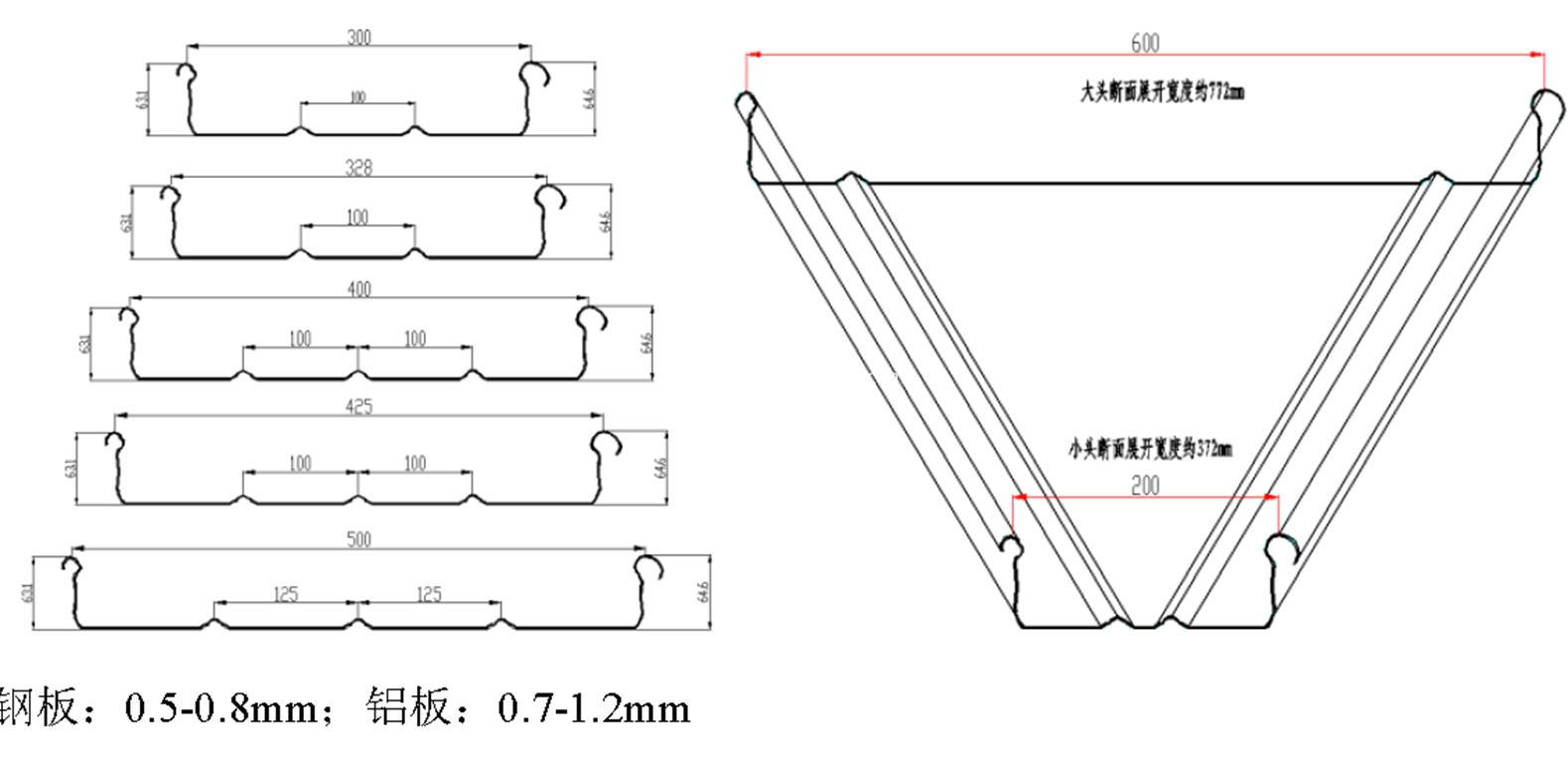

Below is the specification of the standing seam panel bemo panel rollforming line for your reference:

Technical parameter:

1. main power:4+5.5 KW

2. Hydraulic station: 5.5 kw

3. roll station:14 stations

4. speed:22 m/min (not include cutting)

5. material of roller:GCr15, Quenching, (HB220-260)

6. the surface of roller is coated with chrome, single surface with 0.05mm

1. diameter of shaft:ф75mm 40Cr tempered 9

2. material of blade:Cr12Mov

3. thickness:steel 0.5-0.8 mm Aluminum: 0.7-1.2 mm ( standard 0.9mm) G300Mpa

4. effecitve width: 300/328/400/425/500 mm

taper panel: Min.200mm , Max. 600 mm

5. the sheet is subject to the People`s Republic of China construction GB/T 12755-91

6. frequency converter:YASKAWA

7. computer adopt PLC& Touchscreen: panasonic

8. encoder: Omron

9. Tolerance: 3 meter+-1.5mm

Working flow is same with the other tile making machine metal panel rollforming lines, metal coil de-coiler, feeding leveller,main roll forming,hydraulic cutting and receiving table.

Straight panel Tapet panel bemo panel rollformer produce the standing seam panels in big quantity, for the installation of standing seam panel, it need some other special tools, the manual seam locker, the automatic seam locker, the standing seam panel accessories, if you need more information about this standing seam panel and standing seam panel rollformer line, you can send me an inquiry as below instruction through this website, i will receive the inquiry and give you an effective feedback at first time!

.png) Contact Now

Contact Now