Product Description

Advantages of matel sheet making machine

10 Years Long Life Time !!!NO Distort !!!

High Automatic !!!

1)machine structure:wall panel structure

2)Main power:8-9KW siemens motor

3)Forming stations:22 stands for IBR profile

4) Way of drive:1.0"single row chain drive

5)Diameter of shaft:80mm

6)Max rolling speed: 12-15m/min

7)Thickness: 0.3-0.8mm galvanized steel or prepainted sheet,G550Mpa

8) Material width:925mm/1200mm/1250mm

9)Material of roller:polished and coated with chrome, surface with 0.05mm

10)Material of blade mould:Cr12, quenched 58-62

11)way of cutting:hydraulic mould cutting(stop to cut)

12)Length cutting tolerance:+/-1.0mm

13)Hydraulic pressure :16Mpa

14)Hydraulic power:4kw

15)Computer Control system:PLC control from Taiwan

16)Omron encoder measure the length ,made in Japan

17) Electrical requirement:380V,50Hz,3Ph

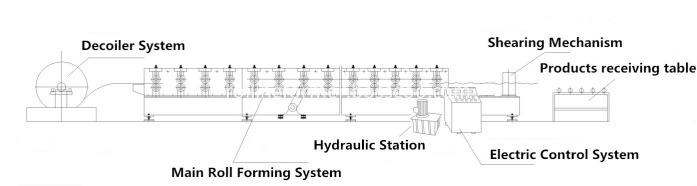

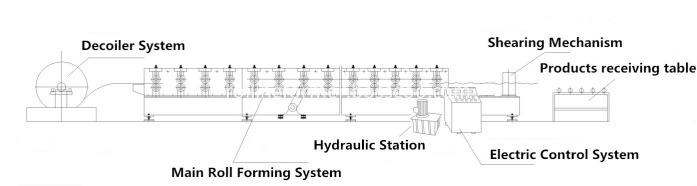

working process of matel sheet making machine

decoil---shape---shear---receive final product

shearing part of matel sheet making machine

shearing parts adopts double advanced pillar structure. It will ensure blade move smoothly.

Besides, we improve the inner structure of pillar. New model of pilllar can minimum friction.

rollers of matel sheet making machine

.Compared with normal rollers, this new model roller quench twice times and prolong heat treatment time.

More over, it is equited with 2-3mm chromed seamless spacers.

feeding part of matel sheet making machine

its feeding part adopts support bench,which will ensure raw material to go inside more smoothly.

Besides, the shearing blade is quenched. It is very easy to shear up to 1mm matel sheet.

control system of matel sheet making machine

it adopts small control box. Compared with old control cabinet, it will save room.

More importantly, it can work directly,because workers no need to connect any cable or wire.

Hydraulic station of matel sheet making machine

To improve stability and prolong life time, this machine adopts powerful hydraulic station.

it adopts national standard motor.

our customers check machine before shipment.

we supply professional technology training for customer.

Backed with 15 years enginner team, we can solve all problem before shipment.

Besides, we offer videos and manual for installation

.png) Contact Now

Contact Now