Product Description

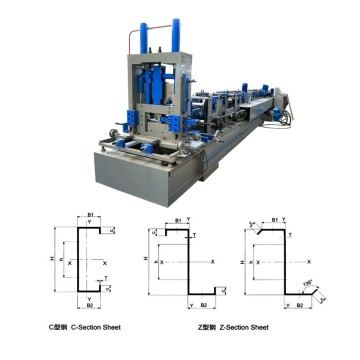

Steel purlin Z profiles roll forming machine

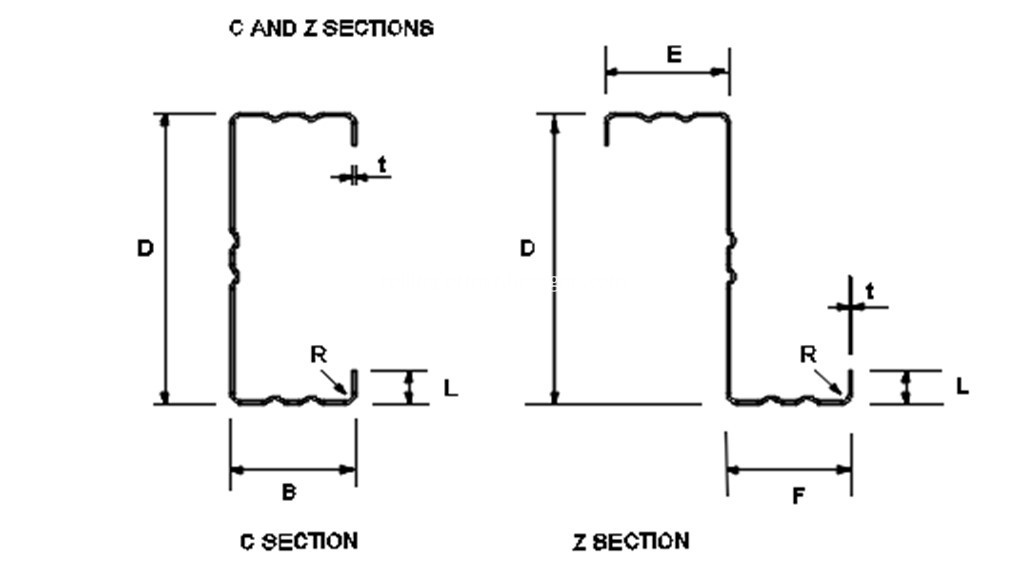

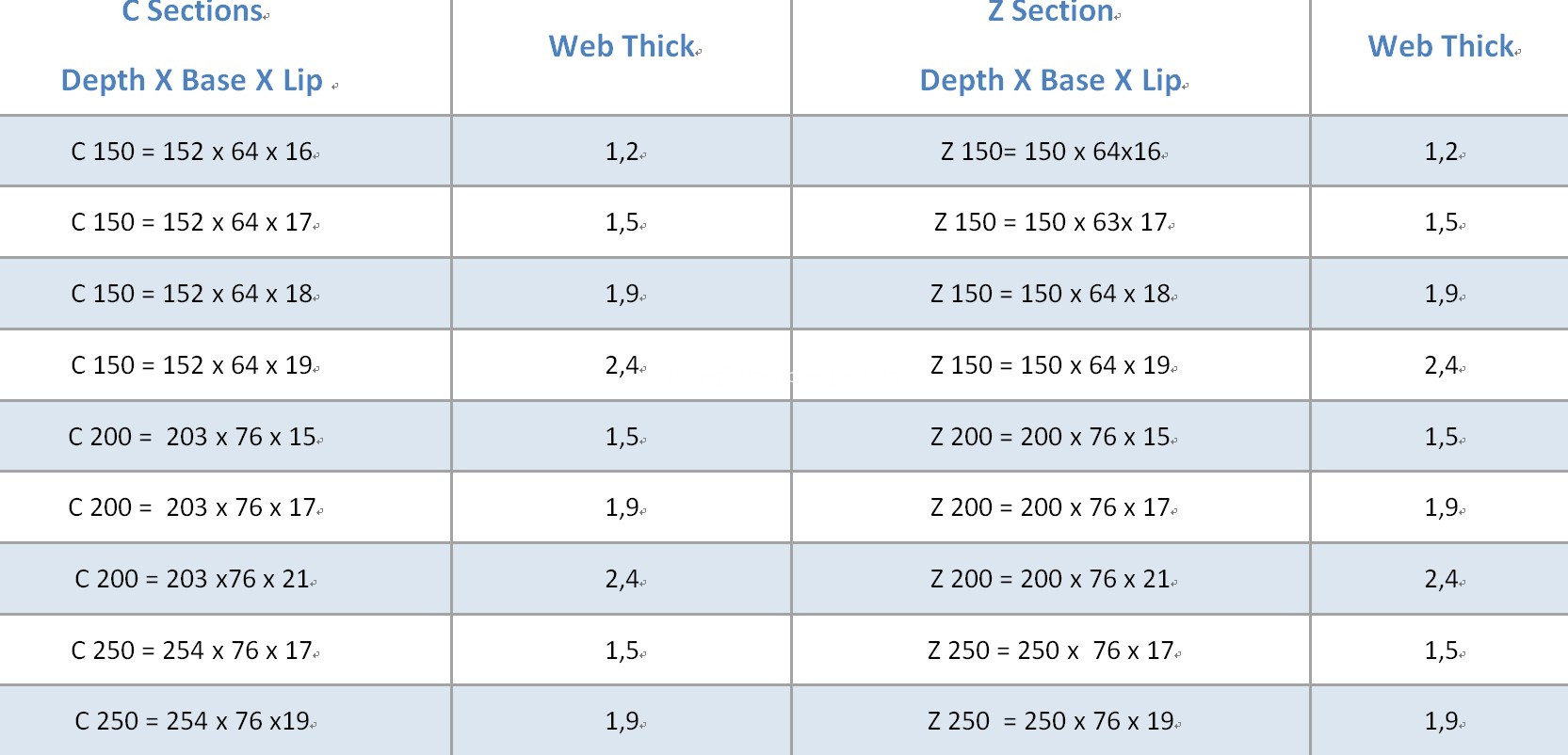

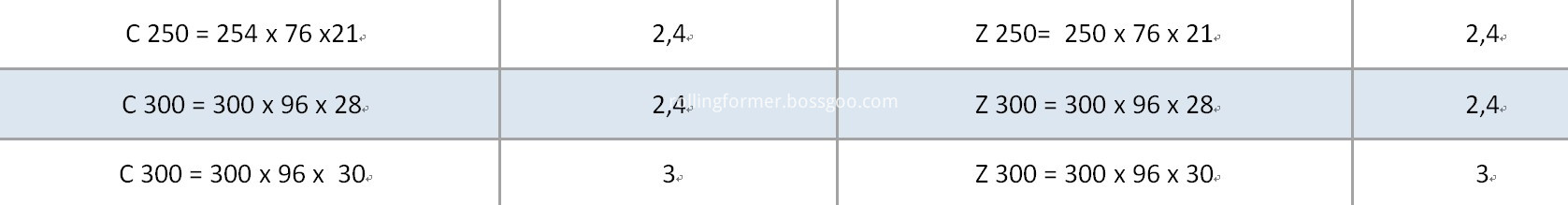

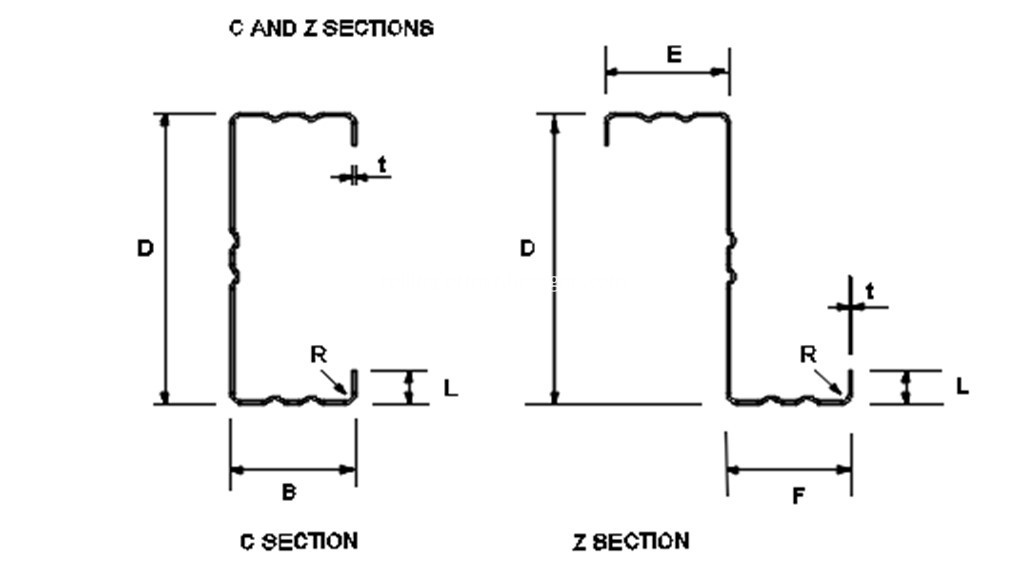

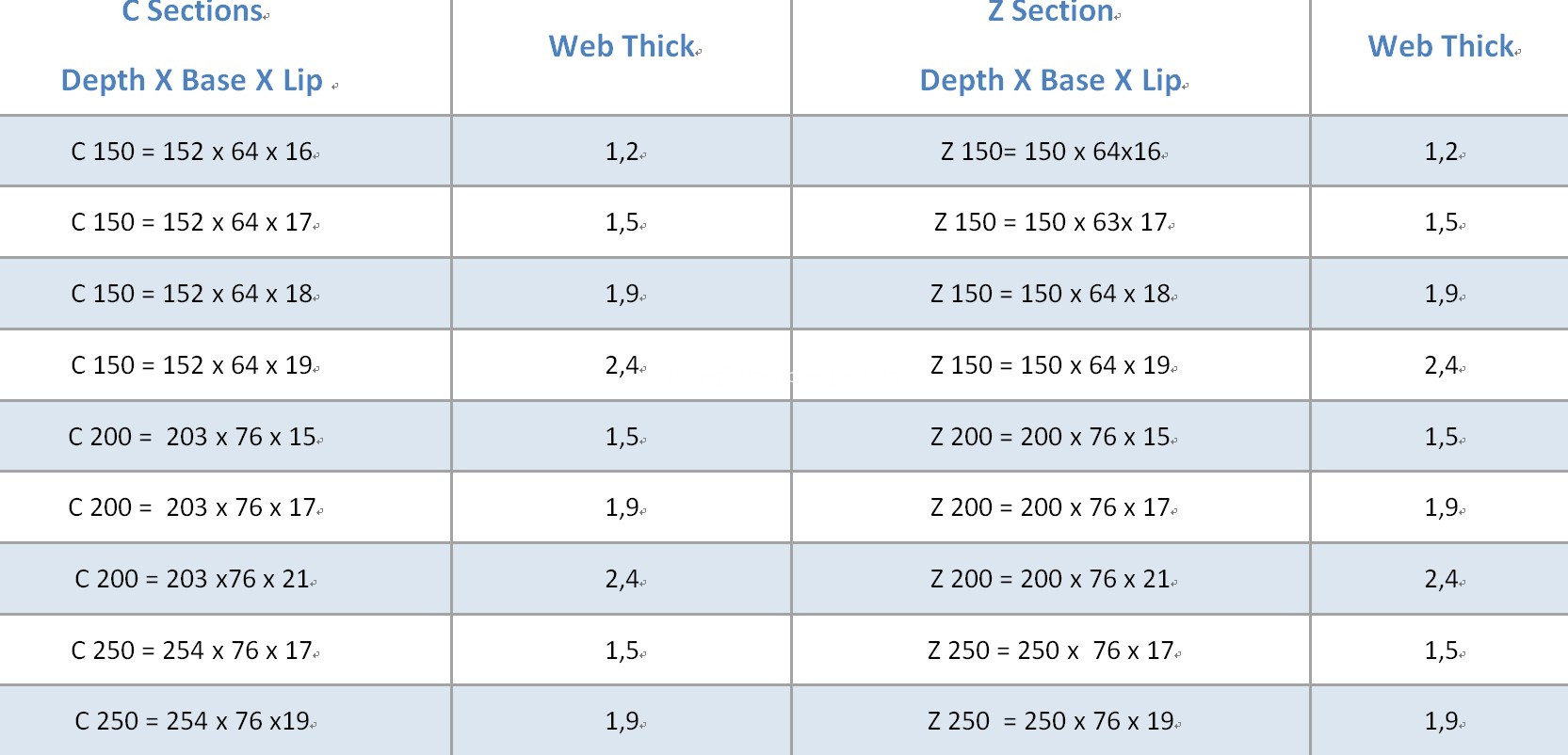

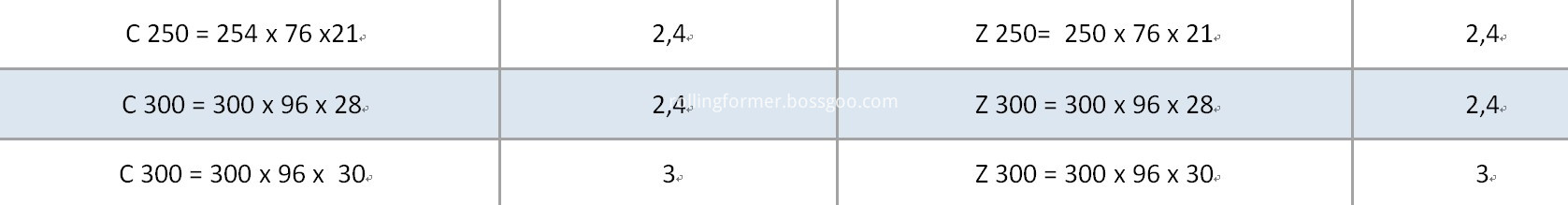

Steel purlin profiles roll forming machine is a line which can produce different sizes of C purlines and Z purlins. The character of this steel purlin profiles roll forming machine is with low cost, and easy to change the space to adjust the size. The thickness of this C section and Z section purlin is 1.5-3.0mm, size is from 80-300mm,100-300mm. For any sizes you need, we will know it and custom design the machine for you. We need to know the flange, the depth, the thickness,the lips.

Processing materials: Q215 Q235 Q345

thickness: 2.0---3.0mm

Hardness : 195mpa---350 mpa

Forming speed: 8m-10m/min

Molding methods:roll forming

Decoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming sysytem

Loading capacity:5T

Uncoiling width:1000mm

Inner diameter: 450-550mm

Feeding

Usage:Put the raw material(steel plate) through the beach to manufacture and process,4 down and 3 up , it can guarantee that the products are neat, parallel and everything is uniformity.

Material of axis:45#steel

Number:3 up,4 down

Diameter of axis:100mm

Forming round:Material bearing steel (GR15), quenching 60-62 ℃

Roll forming machine

Advantage:Automatic length cutting, automatic punching, high degree of automation, quick and easy installation

Z-beam machine is a set of rollers to produce a variety of specifications Z purlin roll forming machine finished single

It consists of passive loading rack, leveling device, punching device, after forming cutting device, hydraulic station, computer control systems. This machine adopts automatic flying saw punching, easy to operate features.

Z section steel rolling machine equipment of Z-beam bending finished with good pressure performance good flatness, automatic fixed-length cutting, automatic punching, high degree of automation, quick and easy installation,

Products can be used as the main medium-sized industrial buildings by the force structures, such as factories, warehouses, machine garage, hangars, exhibition halls, theaters, stadiums, fairs load bearing roof garden sheds and wall level support. Cold-formed steel is the main material for the production of light steel structure, the use of steel or steel roll forming steel.

Length of the main part:6800mm*800mm*1200mm

Weight of main part: 6.2 tons

Voltage : 380V 50HZ 3Phase

Frame : 400 H steel

Drive mode: differential gear

Main axle material :GR15

Material of shafts: 45# steel

Diameter of shafts: φ80mm

Number of rollers : 12 rollers

Main power: 11kw(cycloidal planetary gear speed reducer)

Forming speed: 8m-10m/min

Adjustment method: Half seams type Looper

cutting part

Features: The hydraulic broken Z-beam machine roll bending finished with good compression performance, good flatness, automatic fixed-length cutting, automatic punching, high degree of automation, quick installation

Main power:4kw

Punching part

Features: punching is added to the flying saw cutting part, by the hydraulic control, mainly in the red c-shaped steel in the hole based, can be set up according to their needs, can be washed from time to punch, simple to use, the durability

Power: 4kw (double valve)

Cylinder: 2

Material: Cr12 quenching

Quantity: 2

Hydraulic station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job

Power:3kw

Hydraulic oil: 46#

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

Electric Control System

1.Adopted PLC , transducer, touch panel from Mitsubishi Japan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Schneider

3.Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety.

Counter

One counter gauges length,pulses,and decides length

Omron encoder for length measurement

Products receiving tables

It adopts welded steel and supported roller to transmit the products.

Accessories

1.Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2. Rubber mat 1 pcs;

3.Bolt spanner 1 pcs

.png) Contact Now

Contact Now