Product Description

High speed Steel framing roofing batten rollforming line

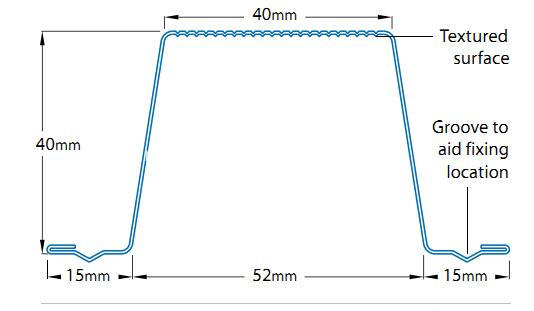

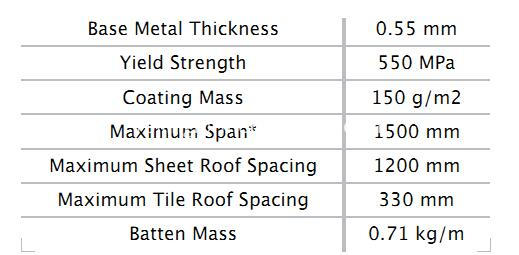

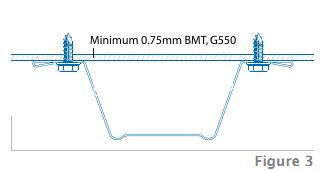

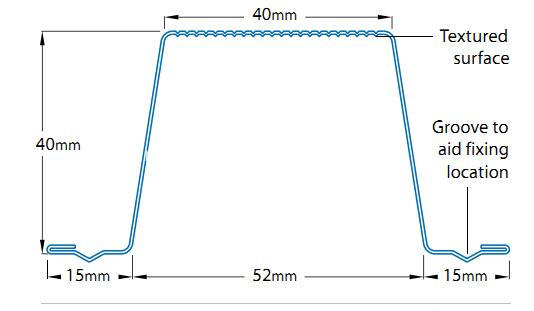

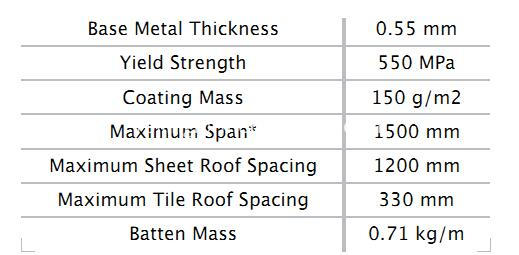

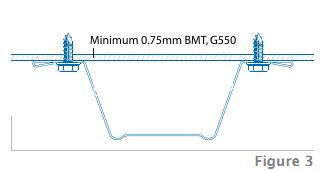

High speed Steel framing roofing batten rollforming line is designed to produce the roofing batten channel automaticlly by the PLC controling computer. Whole steel framing roofing betten rollformer including the de-coiler, leveller, main roll forming machine, cutting system and receiving table. The speed is about 25-35 meters per minutes. Two Cutting method, one is stopping cutting, the other is tracking cutting.Full automatic rollfomer which is controlled by the panasonic PLC. The roofing batten material is hitensile zinc/alum steel and comply with Australian Standard 1397/G550 AZ150. Base metal thickness of the roofing batten is 0.55mm-1.10mm, Yield strength is 550 Mpa, Coating mass is 150g/square meter, Batten mass is 0.71kg/m. Maximum span is 1200mm, Maximum spacing is 330mm. it is high quality steel construction , will help control timber rafter movement, and will assist in preventing the plasterboard roofing from cracking.Celing batten is a high quality channels produced by the rollforming line. It is a widely used economical versatile system, with low weight and cost. Compared with the roofing batten, the roofing batten is higher in the height, and thickness is bigger. Because the roofing batten support more heavier roofing.

The roofing batten rollformer is designed according to the drawing of each sizes roofing batten.

Our factory can produce this roofing batten by the Steel framing roofing batten rollformer.

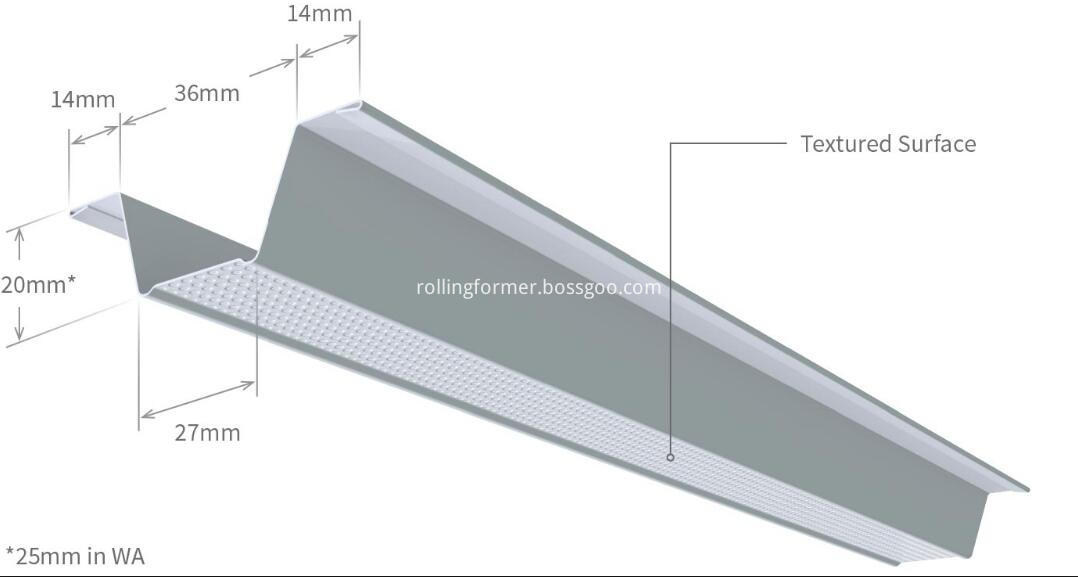

The features of the roofing batten has below features, which is manufactured by the steel framing roofing betten rollformer.

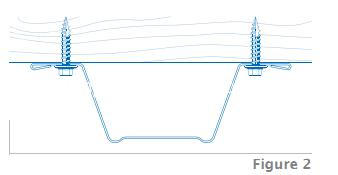

1 the return edges is folded back on itself, providing a safe edge and a rigid profile. In this way, it is safe when person touch the roofing batten. Celing batten rollformer finish this perfect return edges by the designing of each rollers of the rollformer.

2 0.42mm thick hi-tensile steel is very strong, light weight and is easy to cut with snips. The roofing batten rollformer up rollers and down rolllers can be adjusted to leave a 0.42mm space fo the thickness, so there is no damage to the betten material.

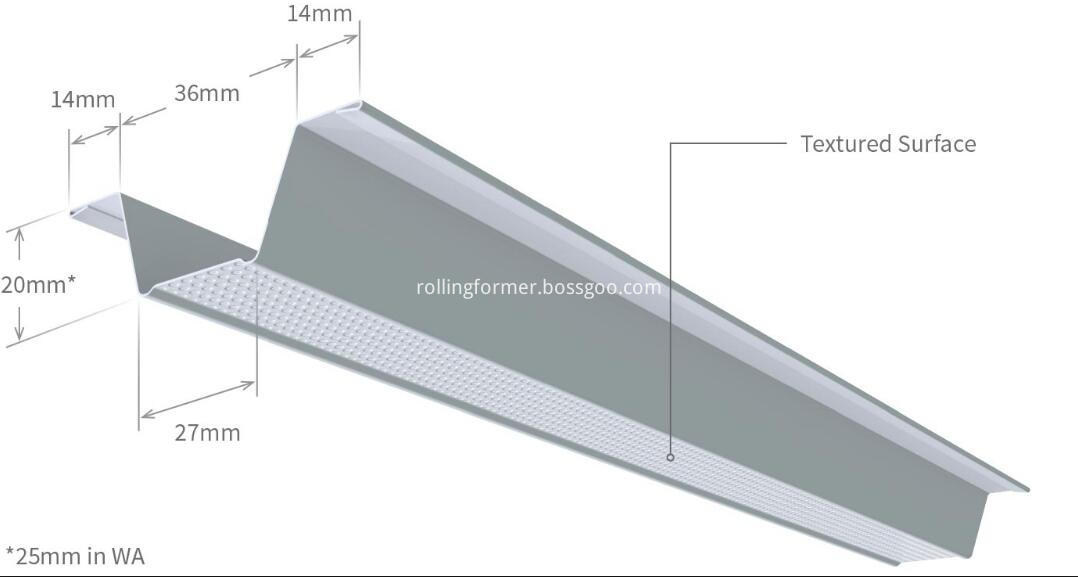

3 The 20mm high profile probided strength and is designed to nest for easy handling and storage. So the roofing batten can be placed one cover another one, also we can design the automatic stacker of the roofing betten rollformer.

4 A cavity on the bottom prolongs the batten's life by proventing condensation from forming. The cavity is formed by the special designing of the rollformer rollers.

5.A textured surface makes installation easy when locating and screwing plasterboard fixings. For the textured surface, the roofing batten rollformer is designed with the embossing rollers. Also the roofing batten rollformer can embossing the logos.

6,roofing battens are supplied in the length of 6100mm per piece, it is easy handling and storage. So you can input the length in the computer, then the rollformer will cut the length as setted, and automatic working and cut.

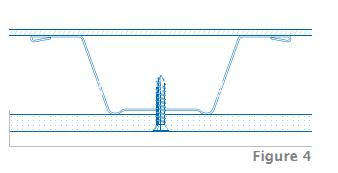

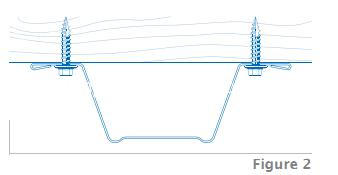

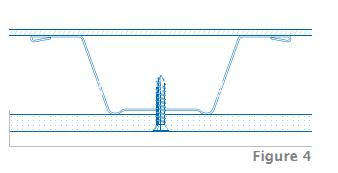

The roofing batten channel The roofing batten can be used fixing to the timber joists, fixing to steel joints, attaching the plasterboard

Above infomation is about the roofing batten which can be produced by our roofing batten rollforming lines.

Below are some specifications of the roofing batten rollformers:

Model roofing batten rollformers

Speed 30-40m/min

Thickness 0.42mm

Controlling Panasonic PLC

Manual De-coiler 2 ton de-coiler

Roller station 13 stations

Post cutting 1 set

Roller material Gcr15 finish machining after quenching HRC58-62℃,chromium coating.

Shaft material and diameter 45# steel finish machining,diameter is ¢70mm

Main power 5.5 kw

Hydraulic press 12 Mpa

Hydraulic power 3 kw

Blade material Cr12Mov, quenching HRC 58-62℃

Length tolearance 3m±1.5mm

Voltage Australia standard voltage 415 V

Transmission 1,0 inch single chain

structural Pillar structure

Color Company color

Size Length*Width*Height 6.5m*1,3m*1.2m

roofing batten rollformers is designed well with high quality material, below are some pictures for your reference:

.png) Contact Now

Contact Now